Electrical Safety Compliance

Jan 2nd 2018

Nearly every workplace uses electricity in some way. From plugging in computers and other electronic devices to working directly on electrical installations, modern workplaces are deeply dependent on electricity. As such, a safe workplace must take precautions against the dangers posed by electricity. According to the U.S. Bureau of Labor Statistics average of 283 employees died per ear from electrical contact , accounting for 4-5% of workplace deaths overall. This article will overview some of the most common safeguards against electrical hazards.

WHAT IS AN ELECTRICAL CIRCUIT?

An electrical circuit is a closed loop through which electrical charges travel. If a circuit is open, improperly grounded, or poorly insulated, it can pose serious danger to human beings. Exposure to electricity can result in shock, burns, cardiac arrest, and death.

THE DANGERS OF ELECTRICAL SHOCK

A shock occurs when a person’s body becomes part of an electrical circuit. This can occur when a person’s body completes a path with two wires of an electric circuit, one wire of an electrical circuit and the ground, or another conductor. The severity of an electrical injury is dependent upon the length of exposure, the amount of current, the frequency of the current, and the path the current takes through the body. The effects of an electrical current can vary from faint tingling to death. From OSHA:

| Below 1 milliampere | Generally not perceptible |

| 1 milliampere | Faint tingle |

| 5 milliamperes | Slight shock felt; not painful but disturbing. Average individual can let go. Strong involuntary reactions can lead to other injuries. |

| 6–25 milliamperes (women) | Painful shock, loss of muscular control* |

| 9–30 milliamperes (men) | The freezing current or " let-go" range.* Individual cannot let go, but can be thrown away from the circuit if extensor muscles are stimulated. |

| 50–150 milliamperes | Extreme pain, respiratory arrest, severe muscular contractions. Death is possible. |

| 1,000–4,300 milliamperes | Rhythmic pumping action of the heart ceases. Muscular contraction and nerve damage occur; death likely. |

| 10,000 milliamperes | Cardiac arrest, severe burns; death probable |

The effects of an electrical shock are not always immediately evident .The severity of an injury can not be accurately judged visually, because serious internal or renal injuries might occur. If an employee suffers an electrical shock, medical attention must be sought immediately, even if you do not think the damage is severe.

Electricity can also cause explosions, which may produce dangerous fire or debris. Even low-energy arcs can cause explosions in highly flammable atmospheres.

TAKING CARE OF THE BASICS

Sockets

Sockets must be completely covered. Exposed wires in uncovered sockets can cause serious electrical shock and injury.

Power Tools and Plugs

Electrical tools should utilize a three-pronged plug. Three-pronged plugs include a ground which helps protect you in case a wire slips out of place. Never bend or remove the ground prong to fit a tool into a two-prong socket. If a wire slips out of place, the electrical current could then flow through the person holding the tool. Modern equipment (usually chargers) that use two-prong plugs are generally heavily insulated and include a plastic, non-conductive casing. Power tools with two-pronged cords must be designated as “double insulated” or include the double-insulation square-within-a-square logo.

Lighting and Wiring

Lighting and wiring should be well-insulated and flexible. Damaged wires should not patched or taped together. Rather, they should be replaced with new, safely insulated wiring.

OSHA Standard 1910.303(b)(7) states: “Electric equipment shall be installed in a neat and workmanlike manner.” Where multiple wires and electrical devices are concentrated in one area, the wires must be clearly labeled and neatly installed. The wires must not be crossed, tangled, or disorganized in any way that could potentially cause confusion.

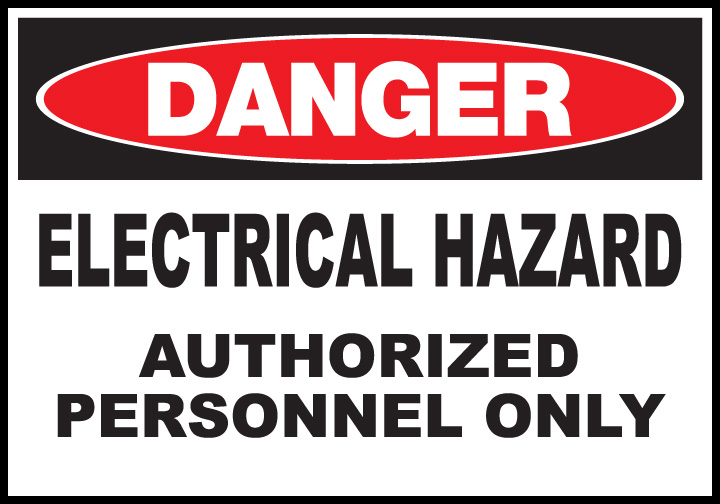

WARNING SAFEGUARDS

Employers are required to install permanent safeguards that alert employees to the presence of electrical hazards. Signage that notifies employees of danger must be clearly posted at the entrance of any room or area that contains an electrical hazard. If signs are not adequate to prevent unauthorized employees from gaining access to dangerous areas, barricades must be installed. If barricades could potentially come into contact with the barricade, the barricade must be insulated. A combination of highly visible signage and protective barricades provides a higher level of protection than signage alone.

LOCKOUT EQUIPMENT

Proper lockout procedures and training can prevent a significant amount of electrical injuries and deaths. A study published in 2006 by the National Institute for Occupational Safety and Health (NIOSH) detailed electrical accidents in the United States from 1992-2002 (NIOSH Publication No. 20031087, Trends in Electrical Injury, 1992-2002). The study found that the failure to properly de-energize electrical equipment caused the second most electrocutions in US workplaces (the first was accidental contact with overhead power lines).

Equipment and machines can store dangerous electrical energy even after the have been turned off. Because of this, machinery must be drained of any residual energy before any maintenance or repair work can safely begin. OSHA’s six step procedure for locking out equipment is as follows:

1. Notify & clear all affected employees

2. Shut down equipment

3. Isolate all related energy sources

4. Apply lockout devices (Use multiple devices if necessary)

5. Release all stored energy

6. Verify energy isolation

It is important to stress during training that locked out equipment can still be dangerous. Locked out equipment must be completely drained of any residual energy and tested for safety before any maintenance work begins.

PPE

If workers must work on electrical installments, they must be provided with insulating personal protective equipment (PPE). Common PPE for electrical work include insulating rubber gloves and sleeves, fire-resistant clothing, face masks, and safety glasses. Prior to beginning work, a hazard assessment must be conducted to determine precisely what PPE are needed. In addition to PPE, workers may also require Insulated Protective Equipment (IPE), including rubber blankets, rubber hoods, and insulating live-line tools.