The Importance of Lockout Tagout: Ensuring Workplace Safety

Posted by Zing Safety on Apr 10th 2023

As the saying goes, "safety first." In today’s fast-paced industrial and manufacturing environments, workplace safety is paramount. Lockout/Tagout (LOTO) controls hazardous energy during maintenance, servicing, or repair. Below, we explore what LOTO is, why it matters, and how to implement it effectively.

What is Lockout/Tagout?

LOTO is a systematic procedure for preventing the release of hazardous energy—electrical, mechanical, hydraulic, pneumatic, thermal, or chemical—while work is performed. Energy can remain stored even after equipment is powered off, so LOTO ensures isolation and verification before anyone begins work.

1) Identify & Isolate

Locate all energy sources and place equipment in a safe state. Use device-specific procedures.

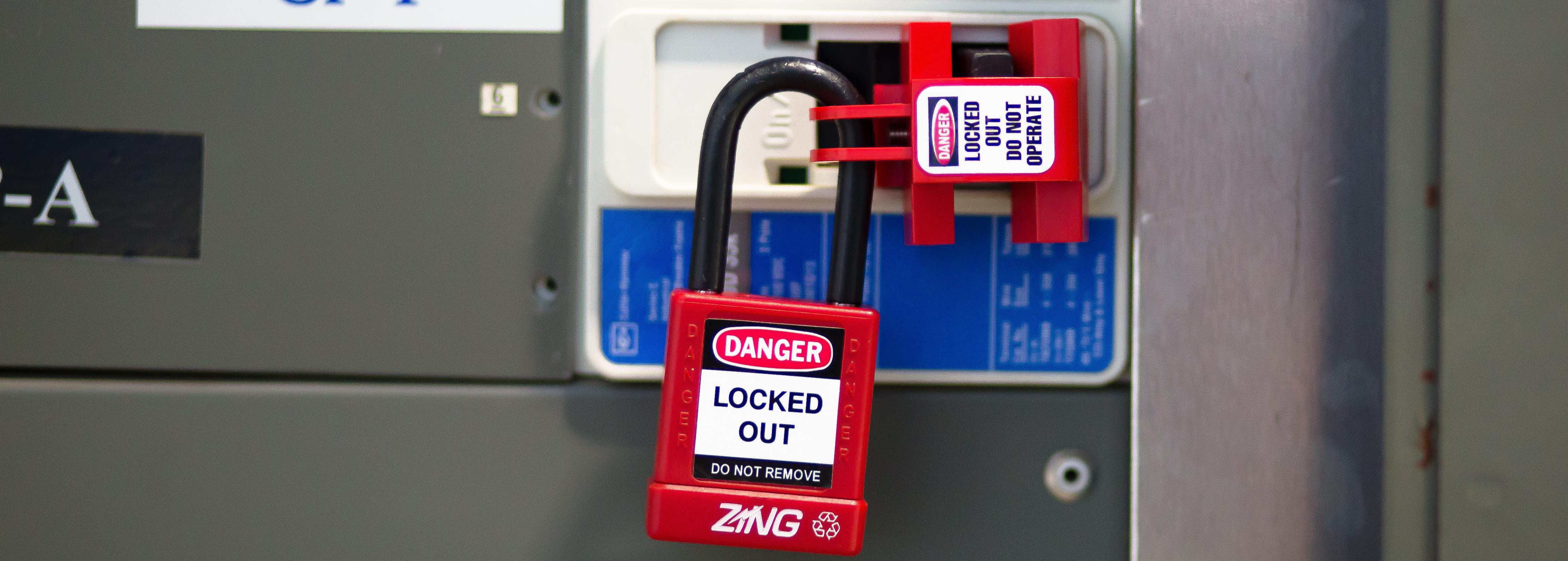

2) Apply Lock & Tag

Install a lockout device (e.g., padlock, hasp, valve/breaker device) and attach a tag communicating status and owner.

3) Verify Zero Energy

Release stored energy and try-start to confirm isolation. Only the authorized person removes devices after work is complete.

Why is LOTO Important?

Protects Workers

Prevents exposure to unexpected startup or stored energy release—reducing serious injuries and fatalities.

Regulatory Compliance

Meets OSHA requirements (29 CFR 1910.147) and other global regulations—your legal and ethical responsibility.

Prevents Equipment Damage

With isolation in place, there’s no risk of accidental startup that could damage machinery, tooling, or facilities.

Improves Efficiency

Clear procedures reduce interruptions and rework—supporting smoother maintenance and higher productivity.

Builds Safety Culture

Demonstrates management commitment and reinforces safe behaviors across shifts and departments.

Compliance in Practice

- Maintain a written energy control program and machine-specific procedures.

- Train authorized, affected, and other employees; retrain after changes or gaps.

- Conduct periodic inspections to verify procedure accuracy and use.

- Standardize devices, keys, and labeling for clarity and accountability.

Pro tip: For complex cells (robots/interlocks), pair OSHA compliance with an ANSI/ASSP Z244.1-style risk assessment and consider validated alternative methods only when traditional lockout is impracticable.

LOTO Quick Checklist

- Device-specific procedures exist and are easy to find at the point of use.

- Locks, hasps, tags, and devices are standardized and stocked.

- Stored energy (gravity, springs, capacitors, pressure) is released or restrained.

- Verification is documented before work begins; try-start performed.

- Only the authorized employee who applied devices removes them after completion.

Outfit Your LOTO Program

Lockout Devices

Valve, breaker, plug, cable & more for every energy type.

Safety Padlocks

Non-conductive, unique keys, engraving & color coding.

Tags & Hasps

High-visibility tags, steel/nylon hasps, group lockout.

Stations & Kits

Wall stations, shadow boards & portable kits.