Discover the Unmatched Durability of Zing Green Safety Products' Lockout Boards

Posted by ZING Safety on Jul 26th 2024

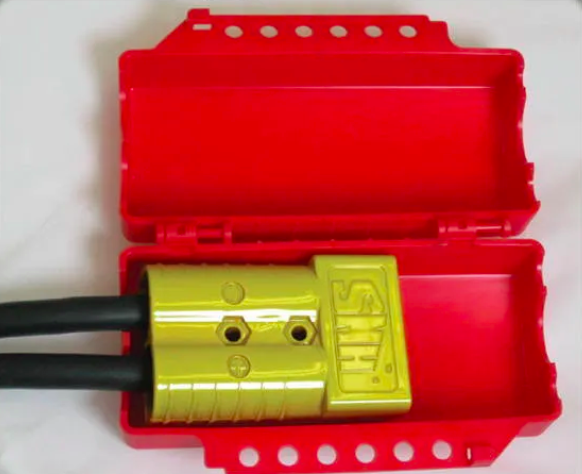

When it comes to safety in the workplace, having reliable equipment is non-negotiable. At Zing Green Safety Products, we prid

read more