Forklift Lockout Safety: Protecting Workers and Preventing Accidents

Posted by Zing Safety on May 24th 2023

Forklifts play a vital role in various industries, but their operation comes with inherent risks. To safeguard workers, prevent accidents, and maintain a safe work environment, implementing proper forklift lockout safety procedures is of paramount importance. In this blog post, we will explore the significance of forklift lockout safety and provide essential guidelines for its effective implementation.

The Importance of Forklift Lockout Safety

Forklift lockout safety is crucial for several reasons. It prevents unintended operation during maintenance, servicing, or repairs, reducing the risk of accidents caused by unexpected movement. Lockout procedures also help identify and address potential hazards associated with forklift operation, promoting a proactive approach to risk mitigation.

Implementing Effective Lockout Procedures

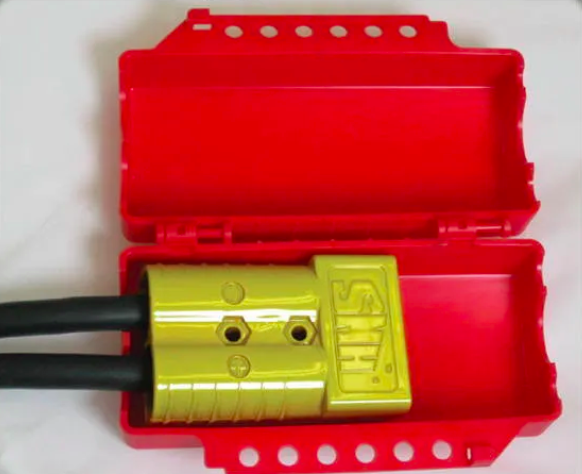

To ensure forklift lockout safety, organizations should establish comprehensive lockout procedures. These procedures should include steps for isolating energy sources, utilizing lockout devices like lockout tags, padlocks, or key-based systems, and conducting proper equipment inspections before commencing work. Thorough employee training on these procedures is essential to ensure compliance and understanding.

Protecting Worker Safety

Worker safety is the primary goal of forklift lockout safety measures. By following proper lockout protocols, workers are protected from accidental activation, collisions, tip-overs, and other potentially life-threatening incidents. Locking out forklifts ensures that only authorized personnel can operate them, minimizing the risk of unauthorized usage and potential accidents.

Compliance with Regulations

Complying with regulatory requirements is essential for any organization. Forklift lockout safety procedures are mandated by regulatory bodies to prevent accidents and promote a safe work environment. Adhering to these standards not only ensures legal compliance but also demonstrates a commitment to worker safety and reduces the risk of penalties or legal liabilities.

Fostering a Safety Culture

Effective forklift lockout safety contributes to the overall safety culture of an organization. By prioritizing safety, providing adequate training, and promoting awareness among employees, organizations can create an environment where safety is ingrained in everyday practices. Encouraging workers to actively participate in lockout procedures and reporting any concerns fosters a culture of responsibility and vigilance.

Forklift lockout safety is a critical aspect of workplace safety that should never be overlooked. Implementing proper lockout procedures, conducting thorough training, and fostering a safety-conscious culture are key to preventing accidents and protecting workers from harm. By prioritizing forklift lockout safety, organizations can create a safer work environment, demonstrate regulatory compliance, and prioritize the well-being of their most valuable asset—their employees. Let's make forklift lockout safety a fundamental part of our safety initiatives and ensure a safer future for all.