A Visual Guide to HazCom Pictograms, Chemical Labels, and SDS

Nov 15th 2016

OSHA’s Hazard Communication (HazCom) standard, effective June 1, 2016, requires that workers fully understand the risks posed by workplace chemicals. The updated HazCom standard is aligned with the Globally Harmonized System (GHS), which provides a universal system for classifying and labeling chemicals.

Under this standard, a detailed, standardized label must be created for every hazardous chemical in the workplace. Labels must clearly communicate the hazards, safe uses, and other key information. This guide provides an overview of the HazCom/GHS requirements, including pictograms, label elements, Safety Data Sheets (SDS), and training.

HazCom & GHS Pictograms

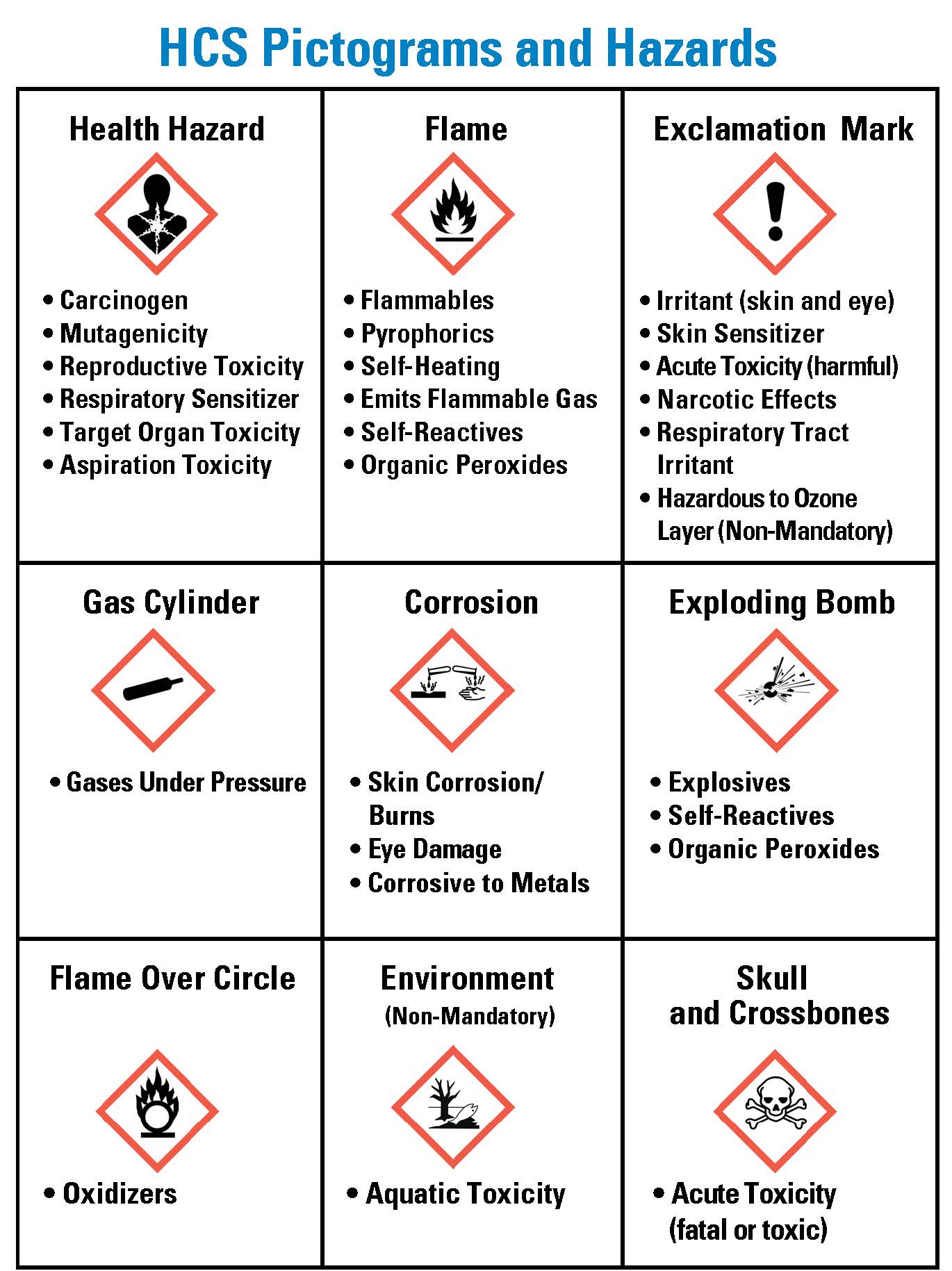

HazCom labels are required to include pictograms. Pictograms are standardized icons that identify the type of hazard associated with a chemical. There are nine GHS pictograms, each representing a different hazard category. Every pictogram features a black symbol on a white background with a red diamond-shaped border. Some chemicals may require more than one pictogram on the label.

Below is a visual guide to HazCom pictograms from OSHA:

Anatomy of a GHS Chemical Label

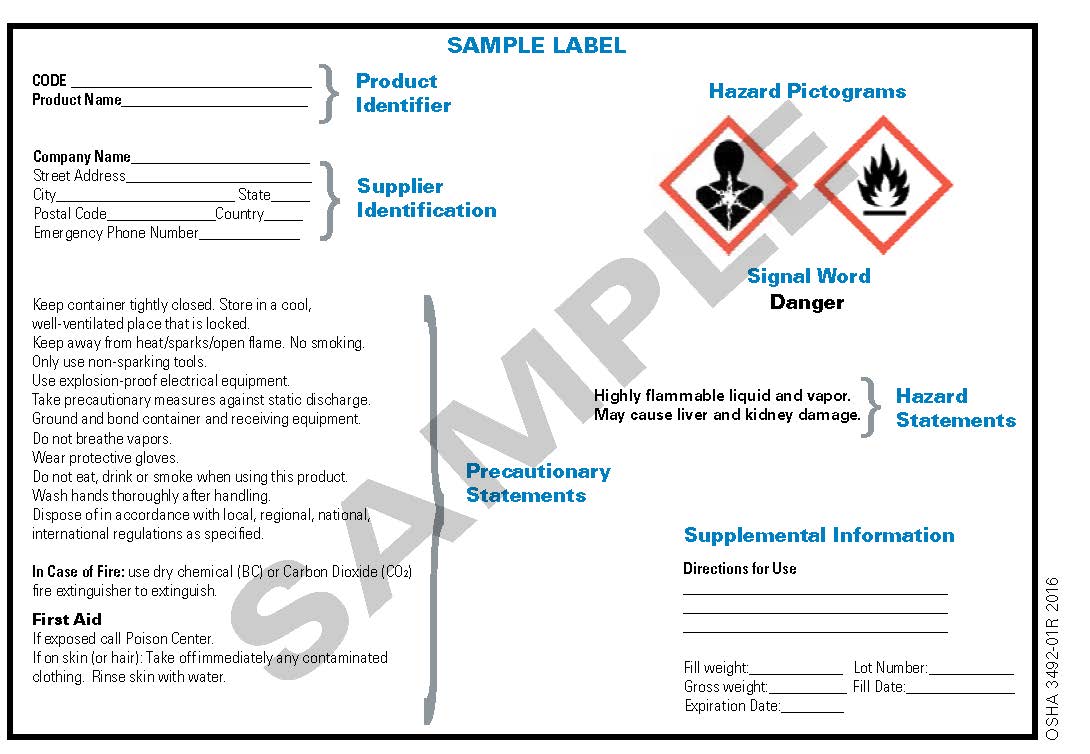

A compliant GHS chemical label includes seven distinct elements. Each label must clearly display:

- Product identifier / chemical name

- Supplier identification (name, address, and contact details)

- Precautionary statements

Precautionary statements explain how to handle, store, and use the chemical safely. They outline required PPE such as gloves, eye protection, or respiratory protection, as well as any other critical safety measures.

- Hazard pictograms

- Signal word (“Warning” or “Danger”)

There are two signal words used on HazCom labels: WARNING and DANGER. “Danger” is reserved for more severe hazards, while “Warning” is used for less severe hazards within a category.

- Hazard statements

Hazard statements describe the specific hazards of the chemical. You can think of these statements as the written counterpart to the pictograms. Hazards fall into three main groups: health hazards, physical hazards, and environmental hazards. Each hazard statement is associated with a code that begins with the letter “H” followed by three digits—for example, H221 corresponds to “Flammable gas.”

- Supplemental information

Supplemental information can include details such as net weight, expiration or manufacture date, and instructions for use. Any additional hazards not captured in the other sections should also be included here.

The graphic below from OSHA illustrates how these elements appear on a typical GHS label:

What Are Safety Data Sheets (SDS)?

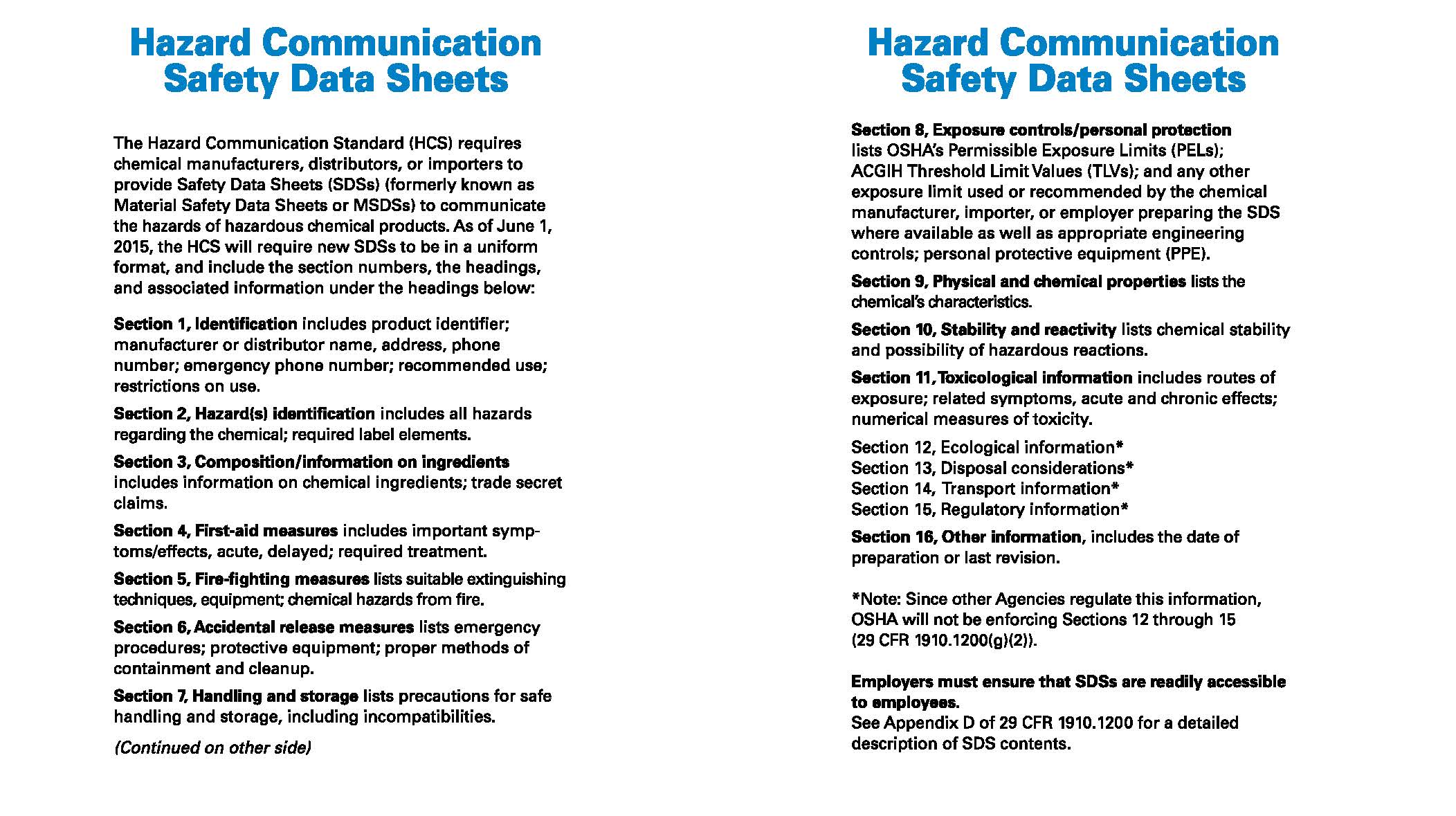

Safety Data Sheets provide detailed information about each hazardous chemical, including its identity and properties, potential health effects, recommended protective measures, and safe storage, handling, and transport procedures.

An SDS is required for every hazardous chemical in the workplace. The revised HazCom standard requires that all SDS follow a standardized 16-section format. This consistent structure makes it easier for workers and emergency responders to quickly locate critical information. OSHA provides a quick card that lists and explains all 16 sections:

HazCom Training Requirements

Effective training is a critical part of any HazCom program. OSHA requires that HazCom training be presented in a manner that employees can understand and apply. Training may use lectures, videos, online modules, classroom instruction, or a combination of methods. Whenever possible, hands-on, supervised exercises should be included so workers can practice reading labels and SDS and handling chemicals correctly.

Employees should be encouraged to ask questions and seek clarification. They must know how to:

- Locate and interpret HazCom labels and pictograms

- Find and read Safety Data Sheets

- Use appropriate PPE and follow safe handling procedures

OSHA requires HazCom training:

- When an employee is initially assigned to work with hazardous chemicals

- Whenever a new chemical hazard is introduced into the workplace

Note that a new chemical does not necessarily constitute a new hazard; for example, adding another corrosive chemical to an area that already contains corrosives may not require new training. For a more detailed discussion of HazCom training best practices, see this article.