Understanding OSHA and ANSI in Lockout/Tagout Compliance

Posted by S. Wright on Oct 20th 2025

Why this matters OSHA’s 29 CFR 1910.147 sets the legal baseline for Lockout/Tagout (LOTO). ANSI/ASSP Z244.1 adds modern best practices—like risk assessments and alternative methods—for facilities with automation, robotics, or complex control circuits.

OSHA: The Legal Minimum for Compliance

OSHA establishes the enforceable requirements every employer must meet to control hazardous energy during servicing and maintenance.

- Maintain a written energy control program and machine-specific procedures.

- Use lockout/tagout devices to isolate energy sources (electrical, mechanical, pneumatic, hydraulic, etc.).

- Provide training for authorized, affected, and other employees.

- Conduct periodic inspections to verify program effectiveness.

Bottom line: OSHA is the must-do baseline—citations and fines apply if you don’t comply.

ANSI/ASSP Z244.1: Best Practice for Performance

ANSI provides voluntary consensus guidance to enhance safety beyond the minimums and address modern technologies.

- Risk assessment framework to determine appropriate control methods.

- Alternative methods (e.g., engineered controls, validated control circuits) when traditional lockout is impracticable—and only after risk reduction is verified.

- Clearer roles, responsibilities, and documentation for complex operations.

- Guidance for automation/robotics, remote operations, and modern diagnostics.

Bottom line: ANSI helps you build a high-performance LOTO program that scales with technology.

OSHA vs. ANSI at a Glance

| Category | OSHA (29 CFR 1910.147) | ANSI/ASSP Z244.1 |

|---|---|---|

| Legal Status | Mandatory; enforceable by law | Voluntary; consensus best practice |

| Primary Focus | Minimum compliance and enforcement | Risk-based controls and continuous improvement |

| Scope | Servicing and maintenance activities | Broader; includes alternative methods and complex systems |

| Goal | Prevent unexpected startup and release of energy | Optimize safety performance and operations |

Quick Start: Strengthen Your LOTO Program

- Document machine-specific energy control procedures (clear, step-by-step; include verification of isolation).

- Standardize locks, tags, and devices by color/ID; issue uniquely keyed padlocks for each authorized employee.

- Train authorized, affected, and other employees; refresh training when processes or equipment change.

- Inspect annually (or more often) and correct gaps discovered during periodic inspections.

- Enhance with ANSI: perform risk assessments; consider validated alternative methods where appropriate.

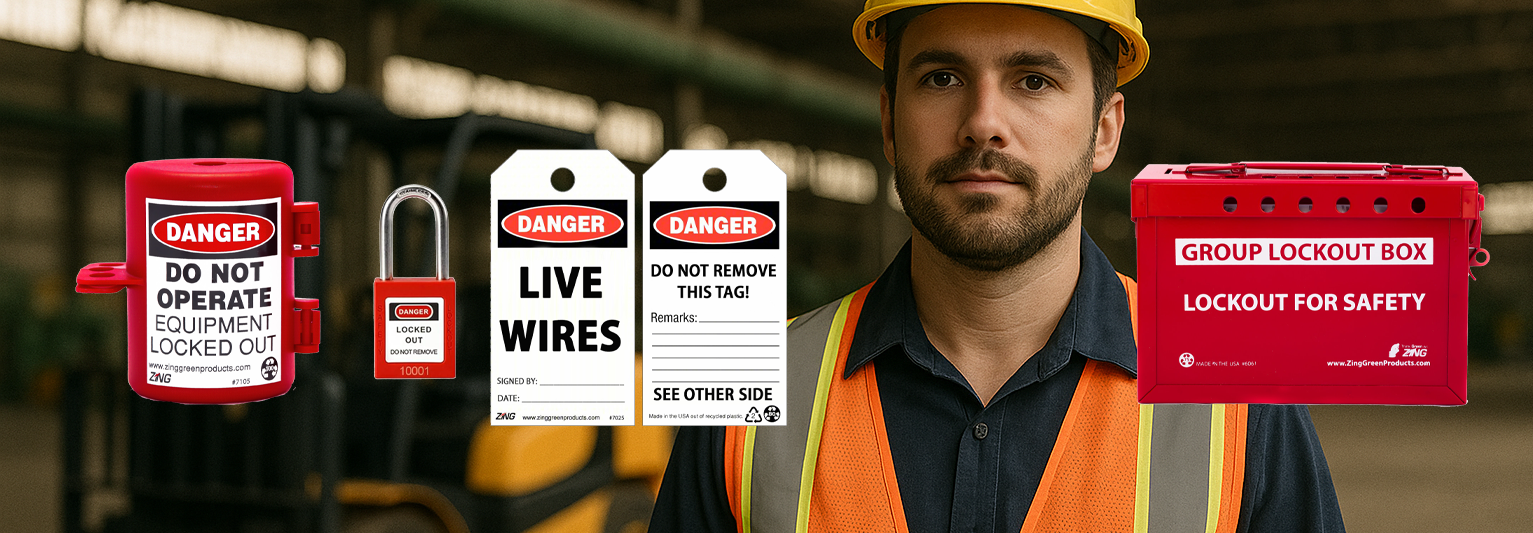

Outfit Your Program with Zing

Lockout Devices

Valve, breaker, plug, cable, and multi-point devices for every energy type.

Safety Padlocks

Durable, non-conductive bodies; unique keys; engraving and color coding.

Tags & Hasps

OSHA-style tags, durable hasps, and identification for clear accountability.

Stations & Kits

Wall stations, shadow boards, and portable kits to improve readiness.

Pro tip: Pair OSHA-required procedures with an ANSI-style risk assessment for complex systems (e.g., robots, interlocked cells). If alternative methods are used, document the validation that risk is equal to or lower than traditional lockout.